LokWorx® Tabs installation

Notice!

For best results, review the following guidelines prior to installation. Shaw will not be responsible for improper installation and failure to follow these guidelines may result in limiting your warranty coverage.

These installation procedures are intended for indoor use to assist in the installation Shaw EcoWorx® and StrataWorx® tile under most job conditions. See Shaw Industries and CRI 104 Commercial Installation Guidelines for specific questions regarding installation not covered within or refer to Shaw Technical Support at 800.241.4014. Any variance from these procedures will become the responsibility of the installer and not the manufacturer. Additional information regarding LokWorx can be found at www.LokWorx.com.

1. Condition Your Site and Test

A proper installation depends on the proper site conditions and product storage. Do not store LokWorx at temperatures exceeding 120°F. LokWorx are freeze-thaw stable; however LokWorx must be allowed to acclimate to site conditions of 65°F prior to application. The following conditions must be maintained for 24 hours prior to, during and permanently after installation:

- HVAC System: Must be operational maintaining the following conditions.

- Temperature: The installation site, carpet and LokWorx must be between 50°F and 95°F. Do not begin the installation if the subfloor temperature is below 50°F.

- Humidity: The installation site’s ambient relative humidity must not fall below 40%.

- Moisture: Conduct relative humidity testing. Results must be below 85% (ASTM F-2170) or the Anhydrous Calcium Chloride test must not exceed 5.0 lbs. per 1000 SF per 24 hours ASTM F-1869 test). (2.27 kg/92.9m2/24 hours). Shaw recognizes RH as the qualifying standard.

- pH: Conduct pH testing on the floor in several locations. A reading below 5.0 or above 12.0 (ASTM F-710) requires corrective measures.

Do not begin the installation if an unacceptable moisture level is detected. Contact Shaw Technical Support for additional recommendations. If excessive moisture is present, the general contractor or building owner must be advised and a decision made if the installation is to begin. Shaw Industries will not be responsible for any moisture related installation failures if these guidelines are not strictly followed. Carpet tiles and LokWorx are not intended to be a moisture barrier against hydrostatic pressure in concrete.

2. Prepare The Floor

The floor must be smooth and level removing any previous adhesives in order for LokWorx to bond the carpet tile securely to the subfloor. Fill depressions or cracks with a cementitious patching / leveling compound that meet or exceed Shaw Industries maximum moisture level and pH requirements. Use of gypsum-based patching and/or leveling compounds which contain Portland or high alumina cement and meet or exceed the compressive strength of 3,000 psi are acceptable.

For cracks or saw cuts deeper than 1", follow the preparation and application instructions for Shaw QuikFill. QuikFill is a 2-part urethane treatment that prevents future damage from moisture penetrating to the surface of the slab that may damage or breakdown adhesives or unapproved patching compounds.

You may use wax-based (green) sweeping compounds if you sweep and remove them immediately.

The substrates must be structurally sound, clean, level and dry. The substrate must be free of dust, dirt, oil, grease, paint, curing agents, concrete sealers, adhesives, loosely bonded toppings, loose particles and any other substance or condition that may prevent or reduce adhesion.

NOTE: Do not sand or scrape Vinyl Asbestos Tile (VAT) without proper attention to abatement procedures and precautions in accordance with all state and local codes. Shaw Industries makes no claims as to the acceptability of this procedure as a mitigation method in lieu of asbestos removal; and accepts no responsibility if any loose asbestos containing floorings are affected upon removal of a Shaw Industries product.

CAUTION: Do not allow cutback asphaltic adhesive or any other non-approved adhesive to come into contact with new adhesives. Installation failure could result. If this situation arises, contact Shaw Technical Support.

3. Prepare Existing Adhesive

Dusting/Powdering of Concrete: Damp mop the subfloor as dusting and powdering will interfere with the adhesion. As water becomes contaminated, make sure to exchange with clean water as needed.

Patch, Leveler, Lightweight Concrete: Prime the surface with a paint roll application ofliquid latex such as Shaw 9050.

VCT and VAT: All tiles must be secure to the subfloor. Existing surface wax does not need to be removed.

Wood Subfloors: Floors must be Wood Association Approved and primed with a paint roll application of liquid latex such as Shaw 9050.

Raised Access Flooring: All panels must be smooth, level, secure and free of any adhesives or material that will affect the adhesive bond. Carpet tiles must be installed offset from access panel seams. Gaps between panels must not exceed 1/16" (1.6 mm).

4. Lay Out Your Site

-

Start the modular installation as near to the

center of the room as possible and position it

to use the largest perimeter cut tile size.

-

Snap a chalk line parallel to one major wall

bisecting the starting point. It may be necessary

to offset the center chalk line to assure perimeter

tiles will be at least half size.

-

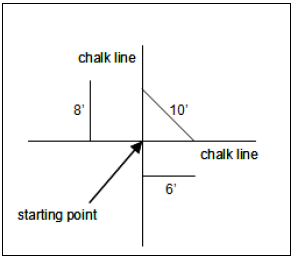

Snap a second chalk line from the starting point

at 90° to the first line. Use a 3-4-5, 6-8-10, or larger

triangle depending on the room size. Meters or feet

may be used to lay out the triangle in these proportions.

|

|

5. Apply LokWorx

Directional arrows are featured on the back of the tile. Numbers within the arrows are for manufacturing purposes and are not related to installation. Apply LokWorx tabs to the backing of the tile following the tab instructions.

Securing LokWorx to the Subfloor

Floating LokWorx Over the Subfloor * (secure the perimeter tiles to subfloor)

6. Install Your Tiles

See product specific installation guidelines for additional information. Install each full carton and complete an entire pallet before starting another pallet to minimize product variation. Each tile has directional arrows on the back. These arrows allow for one-directional or multi-directional installation. Some styles may be large scale or linear in design and require quarter turning. If you are unsure about whether or not your product requires a quarter turned installation, please call 800.241.4014.

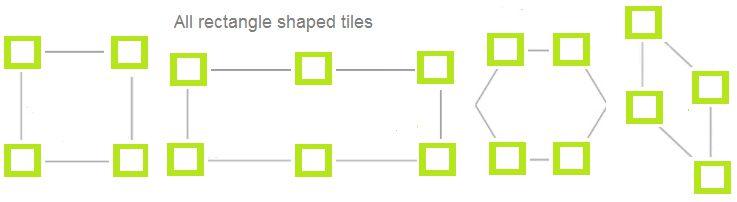

- Carpet tiles come in various sizes and shapes. All Shaw tiles have directional arrows on the back of the tile. This facilitates the installation method which is based on the recommendations of the product or the preference of the customer.

- Remove the LokWorx tab liner according to tab instructions when securing the tile to the subfloor.

- Position the tile to prevent yarn from being trapped between the tiles. Trapped yarn will adversely affect the appearance of the installation and will cause alignment problems.

- Tiles must fit snugly, but not be compressed. Press the entire surface of the tile to ensure adhesion when securing the tile to the subfloor. Check for fit by measuring the length of ten full tiles after installation. The measurement must not be less than, or exceed by more than 1/4 inch, the length of the tiles being multiplied by ten. For example: if 24" X 24" tiles are being installed, the measurement should be between 240 and 240 1/4 inches.

- Roll the entire installation with a 75 lb. or greater roller to assure proper adhesion to the substrate.

Flatwire Cable Systems

Flatwire cables should be installed on top of any existing adhesive and centered underneath the carpet tile for better seam quality. The placement of LokWorx tabs will have to be adjusted to secure the carpet tile to the subfloor.

7. Cut Your Tiles

- A performance feature of LokWorx is its ability to secure the perimeter and any cut tiles in the installation. For ease of installation to secure the perimeter, cut the tile to ensure a proper fit then apply LokWorx tabs according to tab instructions. We recommend properly securing the perimeter as well as field cuts as this prevents shifting over the life of the installation. (Note – This is also recommended for floating LokWorx applications.)

- Tiles may be cut by measuring and cutting from the back using a straight edge. Care must be taken to assure the arrows are pointing in the correct direction. Once cut, LokWorx may be applied to the trimmed tile then put into place.

- Tiles may also be cut by letting them cove up the wall and cutting with a carpet knife, wall trimmer or similar tool. Do not compress.

8. Post Installation Care and Protection

- Place plywood over the carpet when exposed to heavy rolling loads.

- Use protective chair mats under chairs with casters. This will prevent excessive wear to the face of the carpet.

- Place a non-staining building material paper over the carpet to protect it when additional construction activity is to take place. Do not use plastic sheeting as it will trap moisture.

For best results, temperatures should remain above 50°F and the ambient humidity should not fall below 40%.