MoistureShield™ Application / Technical data

Description

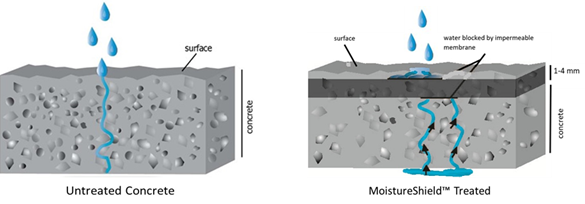

Shaw MoistureShield™ - is a spray applied moisture barrier for concrete, used to create a permanent, and non-film forming membrane 2mm to 4mm below the surface, retaining the original concrete surface profile. The permanent membrane not only protects the slab from external water attack (waterproofing) but also cures and seals, it provides a lifetime moisture barrier and pH mitigation system that will protect slab toppings, coatings, and finished floor surfaces. Cementitious surfaces can be applied after visibly dry. Coatings and flooring can be applied 12 hours after visibly dry.

Shaw MoistureShield™ provides complete versatility, with ease of installation. The concrete mass remains permanently protected and the surface retains its profile for direct installation of coatings, adhesives, cementitious toppings, epoxies and paints. There is no visible change to the appearance of the concrete after being treated with Shaw MoistureShield™

Shaw MoistureShield™ is NOT densification by crystallization, so it DOES NOT work the same as other silicate-based products. Competing silica-based products build crystalline structures inside the concrete and can compete for hydration water during the curing process, and lead to micro-fractures in the slab. Shaw MoistureShield™ is a unique and patented technology that is native to concrete and functions in new or old concrete.

Shaw MoistureShield™- Time of Pour: In a freshly poured slab, Shaw MoistureShield™ acts to promote hydration unreacted Portland cement in the slab in a conversion process to form a protective barrier and increase durability of the concrete. Note: Coverage Rate difference with other applications.

Shaw MoistureShield™ - Sweating Slab: A slab experiencing sweating slab, an older, cured concreate slab, Shaw MoistureShield™ targets the unreacted materials in the slab to form an internal protective barrier. Significantly reducing moisture from below the slab to penetrate the surface of the slab. The profile created by Surface Prep EXT will break up the surface tension of the humid hot air condensing on the surface from becoming dangerous. The best combination is air movement along with the application of Shaw Surface Prep EXT™and Shaw MoistureShield™.

Shaw MoistureShield™- General Moisture Mitigation: Shaw MoistureShield™ targets the unreacted Portland to form an internal protective barrier. Significantly reducing moisture from below the slab to penetrate the surface. This will also control the surface pH that will reduce the reaction of adhesive and floor covering to high pH conditions.

In all cases, the newly formed barrier permanently protects concrete, maintains a healthy pH and provides a long-term solution for other cement-based materials from coating delamination from MVER, water penetration, hairline cracking, surface abrasion and erosion, stains and odors, micro-organism growth, efflorescence, dusting, and other destructive environmental elements.

MoistureShield™ Features & Benefits

-

No VOCs or No HAPs or TAPs

-

Can be used as a curing compound for new concrete, complies ASTM C1315

-

Fully biodegradable and eco-friendly

-

Inhibits ASR & NASR

-

Maintains healthy pH at the surface, Inhibits formation of efflorescence

-

Inhibits osmotic pressure and MVER

-

Permanent internal conversion of the slab top 2-4mm layer

-

Maintains concrete breathability

-

Ready to use single component and easy hand spray application

-

Original appearance of the concrete is maintained

-

Versatile - surface profile is maintained, non-film forming

-

Improved concrete durability and longevity, system continues to improve over time

-

Reduces long-term maintenance and future flooring installation costs

-

Allows direct placement of other coatings, adhesives, and finished floor systems

-

Cost effective - Easy installation, no special equipment, minimal labor

Applications as a Barrier Primer/Sealer

-

New and existing concrete and cement-based materials with a bare untreated surface

-

For indoor and outdoor concrete applications

-

Vertical and horizontal concrete surfaces

-

Above and below-grade, including underground

-

As a curing compound, complies with ASTM C1315

Product Details

| Packaging |

US 4-gallon pail (15.1L) |

| Color |

White Liquid (clears out as it absorbs into slab) |

| Shelf Life |

24 months in unopened containers; Do Not Allow Material to Freeze |

| Dry Time Guidelines |

30 min to 2 hours – pending humidity and air flow |

| Theoretical Coverage |

150-175 SF New Concrete after pour, 225 SF per gallon existing porous concrete |

| Application Temperature |

Should be applied between 38°F (rising) and 90°F |

| ASTM F-3441 |

pH can be as high as 14 |

| ASTM F2170-11 |

Relative Humidity of slab can be 99% to HI RH |

| ASTM F1869-11 |

Lowers MVER 3-5 lbs. initially and continues to improve over time |

|

Example

Concrete Preparation

Note, that in general, ALL substrates must be clean, sound, and have minimum 250 psi tensile bond strength when tested per ASTM D4541. Be sure concrete is free from oil, grease, paint, or any contaminants that would act to prohibit adhesion. Shaw Technical Support recommends

Surface Prep EXT™ for concrete preparation. Do not apply to concrete that has hardeners, curing agents, or densifiers. (Surface Prep EXT™ will remove these applications as well open concrete and profile for proper absorption.) Concrete must be porous, according to ASTM E 3191 Water Droplet Test.

Concrete surfaces can be damp or dry. Shaw MoistureShield™ product should never be pooled on the surface. Shaw MoistureShield™ should be applied in temperatures above 38°F and rising.

NEW CONCRETE SYSTEM SOLUTION: Shaw MoistureShield™is designed to go direct to GREEN concrete, applied in approximately 12 hours from fresh pour, or when a person can walk on the concrete surface without marring it, on broom or wood float porous finish. VERY IMPORTANT – no standing water.

Application

Recommended Equipment:

Depending on the size of the project and age of the concrete, you have options for installation, small areas can utilize a pump sprayer with a cone tip. WARNING! Do not pump to high pressure and aerosol the product, spray with low pressure, large areas new or existing concrete using an airless sprayer (see recommended tip size). While working with an airless sprayer on newly placed concrete, pressure settings must be adjusted to prevent surface etching and damage. It is inadvisable to use centrifugal pumps. Flatwork applications require a low to medium pressure sprayer including an extension wand and with a fan tip spray size of 0.024-0.031 inches (0.61-0.79 mm). Vertical applications can use either installation methods.

Alternate or substitute spray system: Use a store-bought pump sprayer or sprayer used for agricultural spraying dispensing up to 5 gallons per minute (18.93 liters per minute) fan or cone tip spray size of 0.50-1.0 gallons per minute (1.89-3.79 liters per minute).

Crucial Application Procedure: Application in a 50% overlapping pattern is required. For slab installations, place wand upright and vertical to surface at no less than 8 inches and no more than 12 inches (15 -30 cm) from the surface to spray. Important tip can be a fan or cone for complete coverage. Apply product using the prescribed application rate for the area. If pooling occurs or dry areas are discovered during application process, use a fine bristle broom (Dust Push Broom) and spread material evening across application area. Remove any excess material carefully to ensure it does not dry on the slab. Remove or continue to work in excess MoistureShield™ with stiff bristle broom or remove with another appropriate tool such as a squeegee or wet vac.

Note: AT TIME OF POUR - Product left on the slab will require sanding to remove “glaze” look and may be slippery if wet. Shaw Technical recommends treating the full slab for best results but can be applied only in sections with concern. When treating the entire slab is not possible, expand the treatment area beyond the desired area to the nearest control or construction joint. Shaw MoistureShield™ is a penetrating concrete treatment that is spray-applied once bleed water is not present, and it will bare weight of installers without leaving footprints. If concrete control joints are cut after application, reapply MoistureShield™ to the joints or fill with urethane crack fill. It is recommended but all control joints be filled regardless of when they are added.

Note: SWEATING SLAB – Surface Prep EXT™ must be used first to open the concrete and create a porous surface for absorption of MoistureShield™. The Surface Prep EXT™ should be fully removed and a damp (no standing water) floor or dry to receive MoistureShield™ as the final application (see method and application rate). If control joints, expansion joints or existing holes from old bolts are present fill with a urethane crack fill before application of Surface Prep EXT™.

MOISTURESHIELD™ APPLICATION RATE

Existing Concrete - 225 sq. ft. per 1 gallon (4.9 m2 per 1 liter)

Existing Moisture Mitigation or Sweating Slab - Time of Placement – 150-200 sq. ft. should be used at the time of placement. This is defined as applying product within 24 hours of final finish on horizontal surfaces. Apply MoistureShield™ after final troweling has been completed and concrete can take foot traffic without damage without any standing water.

Note: Concrete Finish - An important component of MoistureShield™ product application process is the concrete surface finish. To ensure a successful installation process, discuss the surface finish prior to concrete placement with the concrete foreman and the superintendent. IMPORTANT! Troweled surfaces must be finished in open, unburnished, porous, avoiding a “tight” or black surface finish is mandatory. MoistureShield™ necessitates an open matte, porous (use ASTM 3191 -16 to determine if finish is porous, allowing MoistureShield™ to penetrate the concrete and perform as intended. Shaw Technical suggests meeting with GC and concrete finishing crew and request a wood trowel/float finish for maximum porosity. Burnished or Black finishes will require an initial prep step with Shaw Surface Prep Ext™ to open the surface and porosity for acceptance of Shaw MoistureShield™

Admixtures

The use of moisture vapor reducing admixtures (MVRA), integral waterproofing admixtures, or latex admixtures should not be used when utilizing MoistureShield™.

Accelerators

It is common practice to use an accelerator to speed up the setting of the concrete during winter months. Please note, these products will have the same impact on the action of MoistureShield™. Always check batch tickets and document. Installers must sample test an area before beginning the application process. Accelerators can be inconsistent batch to batch, continue test areas throughout the project. The test areas can vary in dimensions but equate to 9-10 sq ft. Apply MoistureShield™ to the test area broom in as directed and wait 30-45 minutes. In the unlikely event that MoistureShield™ does not absorb after brooming and stays creamy, continue to test until the MoistureShield™ maintains remains unaltered from its standard process and consistency. Once MoistureShield™ shows signs of penetrating after one soft brooming in both directions on a test area for a minimum of 30-45 minutes, full application can begin.

Topically Applied Concrete Products

There on many products on the market, we don’t recommend them with the application of Shaw MoistureShield™. The variance of these products could work but most will not. If a curing compound is used prior to the Shaw MoistureShield™ application, do not treat the concrete with Shaw MoistureShield™.

Environmental Conditions

High temperatures cause fast evaporation, gelling and potential lack of consistency of installation. When surface temperatures exceed 90°F (32.2°C) or below 30% relative humidity, Shaw Technical suggests pre-wetting concrete for a successful application process. Utilize same spray but in a mist versus a full spray directly in front of MoistureShield™ application to assist in preventing quick evaporation of MoistureShield™ and increase penetration. To ensure penetration, continuously broom in product until no visible product on the surface. MoistureShield™ should be removed or worked in before allowing too dry on top of slab as a coating. If this occurs, allow to fully dry and remove with a 60-grit sandpaper on a floor rotary buffer.

Windy Conditions

Wind conditions creates a scenario where product may not fully reach the surface. In the event wind speed exceeds 10 MPH, you will need to shroud the spray tip and keep consistently 8-10 inches from surface.

Cold Weather

Cold Weather include low temperature application and potential accelerator addition to the concrete. The minimum air and concrete temperature at which MoistureShield™ can be applied is 35°F and rising (1.7°C). It is preferrable to begin at 41°F. If an accelerator has been mixed in the concrete, always test a small area as described in the Accelerators section of this document. Dry times can be longer with the low temps but high humidity, MoistureShield™ application must be installed early in the day based on shorten days. Avoid installing when you have a decreasing temperature and if the concrete company may need to protect the concrete with blankets or other means.

Moisture Occurrence

A rain event examples, heavy dew or mild rain that is sufficient to cause standing water on the concrete structure. A light mist is without standing water is not an issue and application does not require further attention. In the event moisture creates standing water during an application, the application completed of the slab that has been treated and visibly dried is considered installed. Portions not visibly dry when standing water accumulates, will require MoistureShield™ products will require reapplication after the added water has dried. IMPORTANT: Ensure area which was properly treated has been notated (tape or chalk line) to ensure proper placing for resuming application. After added moisture has dried or at a minimum is not pooling, example would be damp or slightly darker surface color. Installation can proceed as noted in Installation process. IMPORTANT: start from point of last point of success. Post-Installation walk on traffic is allowed when product is visibly dry after application. Heavy load traffic can be allowed after 4 hours. Control Joints MoistureShield™ requests that control joints are cut after MoistureShield™ have been applied. If the control joints are cut prior to the placement of MoistureShield™, the area will need to be cleaned to remove the residual dust then apply Shaw Quikfill following the preparation and application instructions. QuikFill is a 2part urethane treatment that prevents future damage from moisture penetrating to the surface of the slab that may damage or breakdown adhesives or unapproved patching compounds. MoistureShield™ should be installed with a low-pressure sprayer, working from side to side to ensure complete surface coverage overlapping 50% has with most spray applied densifiers and cure and seal applications. Surfaces should be well saturated, in accordance with the specified application rate of 150-175 sq.ft. /gallon (New), 225 sq.ft. / gallon (Retrofit). If treating a vertical surface, start at the bottom, spraying horizontally back and forth working up the wall. Surfaces with low absorption rate may require agitation (scrubbing) to assist in product penetration. Do not dilute the product.

ACTIVATION PERIOD / DWELL TIME:

Product begins activation immediately and will continue to react in the presence of water. Results will be noticeable within 24 hours.

MAINTENANCE:

No special maintenance required. Clean surfaces as needed.

STORAGE & HANDLING:

Shaw MoistureShield™ Protect from freezing. All containers must be sealed properly when stored. All containers must be secured during transport to prevent damage. Lids, caps and closures must be tightened during transport and storage to avoid spillage.

DISPOSAL:

Shaw MoistureShield™ is fully biodegradable. Neutralizing and dilution with water will be required to meet local waste or sewage disposal requirements. Seek advice on local authority requirements before disposal. Spills should be contained and disposed of under the same requirements. Do not mix with other materials.

HEALTH & SAFETY:

Refer to the warning statements on the product container to ensure proper handling and application. Avoid contact with eyes and skin. Wash with water and thoroughly rinse eyes if contact occurs. Wear eye protection and clothing suitable for prolonged contact and exposure to chemicals. Use in areas with adequate ventilation. Product is harmful is swallowed.

Technical Assistance

If you have any questions regarding this product, please contact Shaw Technical Support for further information.

DISCLAIMER:

The information contained in this Technical Data Sheet (TDS) is correct as of the day issued. Shaw Industries, Inc. makes no other representation, warranty or guarantee of any kind, expressed or implied, statutory or otherwise, including without limitation in respect of merchantability, merchantable quality, durability, fitness for a particular purpose, course of performance or usage of trade, howsoever arising. The user is responsible for determining whether the Shaw MoistureShield™ product is durable, fit for a particular purpose or suitable for the user’s method of use or application. Given the variety of factors that can affect the use and application of a Shaw MoistureShield™, some of which are uniquely within the user’s knowledge and control, it is essential that the user firstly evaluate the Shaw MoistureShield™ to determine whether it is fit for a particular purpose and suitable for the method of use or application.

WARRANTY

The data, statements and recommendations set forth in this product information sheet are based on testing, research and other development work which has been carefully conducted by us, and we believe such data, statements and recommendations will serve as reliable guidelines. However, this product is subject to numerable uses under varying conditions over which we have no control, and accordingly, we do NOT warrant that this product is suitable for any particular use. Users are advised to test the product in advance to make certain it is suitable for their particular production conditions and particular use or uses.

All products manufactured by us are warranted to be first class material and free from defects in material and workmanship. Liability under this warranty is limited to the net purchase price of any such products proven defective, or, at our option, to the repair or replacement of said products upon their return to us transportation prepaid. All claims hereunder on defective products must be made in writing within 30 days after the receipt of such products in your plant and prior to further processing or combining with other materials and products. WE MAKE NO WARRANTY, EXPRESS OR IMPLIED, AS TO THE SUITABILITY OF ANY OF OUR PRODUCTS FOR ANY PARTICULAR USE, AND WE SHALL NOT BE SUBJECT TO LIABILITY FROM ANY DAMAGES RESULTING FROM THEIR USE IN OPERATIONS NOT UNDER OUR DIRECT CONTROL. THIS WARRANTY IS EXCLUSIVE OF ALL OTHER WARRANTIES.