RESILIENT SPORTS FLOORING

GENERAL INFORMATION

- All substrates to receive moisture sensitive floor covering require proper moisture testing.

- Use cementitious patching and leveling compounds that meet or exceed Shaw’s maximum moisture level and pH requirements. Use of gypsum-based patching and/or leveling compounds which contain Portland or high alumina cement and meet or exceed the compressive strength of 3,000 psi are acceptable.

- For cracks or saw cuts deeper than 1", follow the preparation and application instructions for QuikFill. QuikFill is a 2-part urethane treatment that prevents future damage from moisture penetrating to the surface of the slab that may damage or breakdown adhesives or unapproved patching compounds.

- It is recommended that resilient floor covering installation shall not begin until all other trades are completed.

- Material should always be visually inspected prior to installations. Any material installed with visual defects will not be considered a legitimate claim as it pertains to labor cost.

- Perform Bond testing to determine compatibility of adhesive to the substrate. 9050 primer can be utilized to promote adhesion.

STORAGE AND HANDLING

- Store all rolls standing upright; do not lay rolls down for long periods.

- When more than one roll of a color is being installed, all material should be from the same batch and the rolls must be installed in consecutive order. If material from more than one batch is to be used, the job should be laid out so that different batch numbers are not installed side by side.

- When installing Resilient Sports Flooring the sheets must be installed running in the same direction.

- Flooring material and adhesive must be acclimated to the installation area for a minimum of 48 hours prior to installation.

SITE CONDITIONS

- Areas to receive flooring should be adequately lighted during all phases of the installation process.

- Controlled environments are critical. Fully functional HVAC systems are the best way to ensure temperature and humidity control.

- DO NOT install resilient flooring products until the work area can be temperature controlled.

- The permanent HVAC system must be operational and functional and set to a minimum of 65°F (20°C) or a maximum of 85°F, for a minimum of 7 days prior to, during, and after installation. Once the installation is complete the temperature should not exceed 85°F.

SUBFLOOR INFORMATION

Note: All substrates to receive resilient flooring shall be dry, clean, smooth and structurally sound. They shall be free of dust, solvent, paint, wax, oil, grease, residual adhesive, adhesive removers, curing, sealing, hardening/parting compounds, alkaline salts, excessive carbonation/Iaitance, mold, mildew, and other foreign materials that might prevent the adhesive from bonding.

WOOD SUBFLOORS

Wood subfloors must be structurally sound and in compliance with local building codes.

- It is recommended that your chosen APA underlayment grade panels be designed for installation under resilient flooring, and carry a written warranty covering replacement of the entire flooring system.

- Double-Layered APA rated plywood subfloors should be a minimum 1" total thickness, with at least 18" well ventilated air space beneath.

- Insulate and protect crawl spaces with a vapor retarder covering the ground.

- Particleboard, chipboard, flake board, OSB, hardboard or similar are not recommended subfloor materials and require the additional layer of a ¼” underlayment grade panel.

- DO NOT install over sleeper construction subfloors or wood subfloors applied directly over concrete.

- Underlayment panels can only correct minor deficiencies in the sub-floor while providing a smooth, sound surface on which to adhere the resilient flooring.

- Any failures in the performance of the underlayment panel rest with the panel manufacturer and not with Shaw Industries, Inc.

- SHAW resilient flooring is not recommended directly over fire-retardant treated plywood or preservative treated plywood.

- The materials used to treat the plywood may cause problems with adhesive bonding. An additional layer of APA rated 1/4" thick underlayment should be installed.

- Always follow the underlayment manufacturer’s installation instructions.

- Crumb rubber underlayments are not an acceptable option for use with resilient floor coverings due to performance issues resulting from chemical incompatibilities.

STRIP — PLANK WOOD FLOORING:

- Due to expansion/contraction of individual boards during seasonal changes a 1/4" or thicker APA rated underlayment panels must be installed over these types of subfloors.

CONCRETE SUBFLOORS

NEW AND EXISTING CONCRETE SUBFLOORS SHOULD MEET THE GUIDELINES OF THE LATEST EDITION OF ACI 302 AND ASTM F 710, “STANDARD PRACTICE FOR PREPARING CONCRETE FLOORS TO RECEIVE RESILIENT FLOORING" AVAILABLE FROM THE AMERICAN SOCIETY FOR TESTING AND MATERIALS, 100 BARR HARBOR DRIVE, WEST CONSHOHOCKEN, PA 19428; 610-832-9585; HTTP://WWW.ASTM.ORG.

- All concrete substrates should be tested for IRH (Internal Relative Humidity) according to ASTM F 2170.

- Substrates shall be smooth, structurally sound, dry, clean and free of all foreign material such as dust, wax, solvents, paint, grease, oils, old adhesive residue, curing and hardening/ curing compounds, sealers and other foreign material that might prevent adhesive bond.

- If the adhesive residue is asphalt‐based (cut‐back), or any other type of adhesive is present, it must be removed by industry accepted methods such as mechanical removal or wet scraping.

- If a chemical abatement has been performed, use Surface Prep EXT to remove any residual chemicals present. Once Surface Prep EXT has been properly cleaned and removed, apply one coat of MRP for additional protection.

- Adhesive removal through the use of solvents or citrus adhesive removers is not recommended. Solvent residue left in or on the subfloor may affect the new adhesive and floor covering.

WARNING! DO NOT SAND, DRY SWEEP, DRY SCRAPE, DRILL, SAW, BEAD BLAST ORMECHANICALLY CHIP OR PULVERISE EXISTING RESILIENT FLOORING, BACKING, LINING FELT , ASPHALTIC “ CUT BACK” ADHESIVES OR OTHER ADHESIVES.

These products may contain either asbestos fibers and/or crystalline silica. Avoid creating dust. Inhalation of such dust is a cancer and respiratory tract hazard. Smoking by individuals exposed to asbestos fibers greatly increases the risk of serious bodily harm. Unless positively certain that the product is a non‐asbestos‐containing material, you must presume it contains asbestos. Regulations may require that the material be tested to determine asbestos content and may govern the removal and disposal of material. See current edition of the Resilient Floor Covering Institute (RFCI) publication Recommended Work Practices for Removal of Resilient Floor Coverings for detailed information and instructions on removing all resilient covering structures. For current information go to

www.rfci.com.

- On or below-grade slabs must have an effective vapor retarder directly under the slab.

- Wet curing 7 days is the preferred method for curing new concrete.

- Curing compounds (DO NOT USE). If present they can interfere with the bond of the adhesive to the concrete. Seek assistance from a substrate manufacturer if curing agents are detected.

- Remove curing compounds 28 days after placement, so concrete can begin drying.

- Concrete floors shall be flat and smooth within 1/8" in 6 feet or 3/16" in 10 feet. F-Number System: Overall values of FF 36/ FL 20 may be appropriate for resilient floor coverings.

- Expansion and isolation joints in concrete are designed to allow for the expansion and contraction of the concrete. Resilient flooring products should never be installed over expansion joints. Expansion joint covers designed for use with resilient floorings should be used. Control joints (saw cuts) may be patched and covered with resilient once the concrete is thoroughly cured, dry and acclimated.

- Required Moisture Testing - maximum moisture level per ASTM 1869 CaCl is 8 lbs. and ASTM 2170 In-situ Relative Humidity 90% per 1000 sq.ft. in 24 hours.

- Concrete floors must be tested.

- PH reading must not exceed 12.0.

- Readings below 5.0 and in excess of 12.0 can affect resilient flooring and adhesives negatively.

NOTE: IT MAY NOT BE THE FLOOR COVERING INSTALLER'S RESPONSIBILITY TO CONDUCT THESE TESTS. IT IS, HOWEVER, THE FLOOR COVERING INSTALLER’S RESPONSIBILITY TO MAKE SURE THESE TESTS HAVE BEEN CONDUCTED, AND THAT THE RESULTS ARE ACCEPTABLE PRIOR TO INSTALLING THE FLOOR COVERING. WHEN MOISTURE TESTS ARE CONDUCTED, IT INDICATES THE CONDITIONS ONLY AT THE TIME OF THE TEST.

LIGHTWEIGHT CONCRETE

All recommendations and guarantees as to the suitability and performance of lightweight concrete under resilient flooring are the responsibility of the lightweight concrete manufacturer. The installer of the lightweight product may be required to be authorized or certified by the manufacturer. Correct on-site mixing ratios and properly functioning pumping equipment are critical. To ensure proper mixture, slump testing is recommended.

- Lightweight aggregate concretes having dry densities greater than 90 lbs. per cubic foot may be acceptable under resilient flooring.

- Concrete slabs with heavy static and/or dynamic loads should be designed with higher strengths and densities to support such loads.

- Surface must be permanently dry, clean, smooth, free of all dust, and structurally sound.

- Perform Bond testing to determine compatibility of adhesive to the substrate. 9050 primer can be utilized to promote adhesion.

- Three internal relative humidity tests should be conducted for areas up to 1000 SF. One additional test, for each additional 1000 SF.

RADIANT HEAT

Radiant Heating: Radiant-heated subfloor systems can be concrete, wood or a combination of both.

The heating systems components must have a minimum of 1/2" separation from the flooring product. The system must be on and operational for at least 2 weeks prior to installation to reduce residual moisture. Three days prior to installation lower the temperature to 65 degrees, after installation gradually increase the temperature in increments of 5° F to avoid overheating. Maximum operating temperature should never exceed 85°F. Use of an in-floor temperature sensor is recommended to avoid overheating. Contact the manufacturer of your radiant heating system for further recommendations.

-

Electric Radiant Floors: consist of electric cables (or) mats of electrically conductive materials mounted on the subfloor below the floor covering. Mesh systems are typically embedded in thin-set. When embedding the system components, use cementitious patching and leveling compounds that meet or exceed Shaw’s maximum moisture level and pH requirements. Use of gypsum-based patching and/or leveling compounds which contain Portland or high alumina cement and meet or exceed the compressive strength of 3,000 psi are acceptable.

-

Hydronic Radiant Floors: pump heated water from a boiler through tubing laid in a pattern under the flooring. Typically installed in channels under a wooden subfloor (or) imbedded in concrete slabs. Requires the installer follow a specific nailing pattern to avoid penetration of the heat system.

RESILIENT FLOORCOVERINGS

- Must be single layered, non-cushion backed, fully adhered, and smooth.

- Show no signs of moisture or alkalinity.

- Waxes, polishes, grease, grime, and oil must be removed.

- Cuts, cracks, gouges, dents and other irregularities in the existing floor covering must be repaired or replaced.

- Embossing Ieveler recommended to aid in proper bonding and to prevent telegraphing.

- Do not install over rubber based substrates.

NOTE: THE RESPONSIBILITY OF DETERMINING IF THE EXISTING FLOORING IS SUITABLE TO BE INSTALLED OVER TOP OF WITH RESILIENT, RESTS SOLELY WITH INSTALLER/FLOORING CONTRACTOR ON SITE. IF THERE IS ANY DOUBT AS TO SUITABILITY, THE EXISTING FLOORING SHOULD BE REMOVED, OR AN ACCEPTABLE UNDERLAYMENT INSTALLED OVER IT. INSTALLATIONS OVER EXISTING RESILIENT FLOORING MAY BE MORE SUSCEPTIBLE TO INDENTATION.

Quarry Tile, Terrazzo, Ceramic Tile, Poured Floors (Epoxy, Polymeric, Seamless):

- Must be totally cured and well bonded to the concrete.

- Must be free of any residual solvents and petroleum derivatives.

- Waxes, polishes, grease, grime, and oil must be removed.

- Show no signs of moisture or alkalinity.

- Cuts, cracks, gouges, dents, and other irregularities in the existing floor covering must be repaired or replaced.

- Fill any low spots, holes, chips and seams that may telegraph through the new flooring.

- Grind any highly polished or irregular/smooth surfaces.

- Quarry tile or Ceramic tile grout joints and textured surfaces must be filled with an embossing leveler or substrate manufacturer approved material.

ADHESIVES

2200 / 4200 / 4151

Installer friendly, premium high strength (non-staining) acrylic adhesive, designed to permanently install SHAW flooring. May-be used on all grades of concrete: on, above, or below grade in the absence of excess moisture, as well as suspended approved wood floors. Refer to adhesive label for additional information. Do not use spray adhesives.

Note: To properly apply 2200,4200 or 4151, snap white chalk lines along areas where adhesive will be spread to ensure an even and straight line of adhesive. Spread adhesive with a 1/16" (wide) x 1/32" (depth) x 1/32” (apart) trowel to cover the chalk line on one side and meet up to it on the other. If glue is spread over the chalk line it will need to be removed. (DO NOT overlap adhesive.) - Troweling new adhesive over an area already spread may result in telegraphing. Be very careful not to leave any adhesive ridges or puddles.

Roll with a 100 lb. roller immediately after flooring is placed, ensuring material has complete contact with adhesive.

IMPORTANT: DO NOT use 2200 / 4200 as a pressure sensitive adhesive. Loss of adhesion can result if the flooring is not installed within the working time of the adhesive. DO NOT allow the adhesive to “skin” over or dry. Too much open time will result in an insufficient bond.

Note: Open time and working times may vary based on temperature, humidity, substrate porosity, trowel size and air flow.

IMPORTANT: Recommended to perform a bond test in order to determine adhesive working time per job site conditions. The strength of the bond test will indicate whether 9050 floor primer is necessary.

9050- PH BLOCKER/FLOOR PRIMER:

9050 is an acrylic solution made to neutralize excess alkali that is also recommend as a primer coat to prevent over absorption of adhesive and to ensure a better bond. Formulated with an antimicrobial agent, it provides protection against bacteria, fungi, and mildew in the wet or dry state. Contains no solvent, alcohol, or other hazardous materials per OSHA 29 CFR 1910.1200. Non-photo chemically reactive per rule #102. Available in 4-gallon pails.

INSTALLING SHEET VINYL SPORTS FLOORING

Installing Sheet Vinyl Sports Flooring:

- Use 2200,4200 or Shaw 4151 adhesive for Resilient Sports Flooring Installations.

- Use a 1/16” wide x 1/32” deep x 1/32” apart U notched trowel only.

- Dimensionally stable (will not shrink or compress). If cut to full may result in a bubble.

- Install all cuts and rolls in consecutive sequence.

- DO NOT reverse sheets for seaming.

- When more than one roll of a color is being installed the material should be from the same batch and the rolls must be in consecutive order. If material from more than one batch is used, the job should be laid out so that different batch numbers are not installed side by side.

CUTTING AND FITTING SHEETS:

Resileint Sports Flooring is very flexible and easy to handle. In most cases, an experienced installer will be able to hand fit the material in areas where base or trim moldings will be installed.

- Measure, identify, and mark your control line for the sheet good installation.

- Cut the required length off the roll, including enough to run up the wall 2" at either end.

- Push the length of the sheet as close to the starting wall as possible, letting the extra length run up the wall at the far end.

- The material should still be aligned on the control line.

- Place a straight edge on top of the material along the starting wall, and proceed to cut along the straight edge. This cut technique is a direct scribe. Pattern scribing or three wall scribing is also acceptable.

- Push the fitted sheet gently to the starting wall while keeping it aligned.

- Free hand knife the opposite wall of the starting wall. Pattern Scribing or direct scribe is also acceptable.

- Continue to free hand knife, pattern scribe, or direct scribe material for the remainder of the installation area.

- Opening up the sheets in the width/length is acceptable.

- DO NOT fold as care should be taken not to crease material.

- Factory edges may be used when seaming solid colors provided.

- Edges are not damaged in anyway.

- Factory edges are laid together with uniform gaps the entire seam length.

- Uniform gap between sheet edges is no wider than a business card is thick.

- Seams may also be out by straight edging one side and under scribing the second sheet.

- DO NOT straight edge and seam, or edge trim and seam.

- Snap white chalk lines along areas where adhesive will be spread to ensure an even and straight line of adhesive.

- DO NOT use permanent marker.

- Carefully push flooring into adhesive, working toward the wall. DO NOT FLOP MATERIAL IN — air may be trapped, causing bubbles.

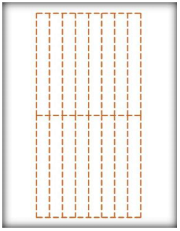

- Sheets can be random staggered but preferably one main seam at the half court line to be hidden by the center painted line. A seam line can then be run perpendicular centering off the basketball hoops inside diameter center point (See Diagram).

- DO NOT reroll material prior to gluing. Instead pull the material back on itself to make it easier to push back into place.

- Sweeping or vacuuming the substrate and material through the entire installation process is essential.

- Recommended to massage curl the end joints to help ensure they lay flat. Putting weight on the and joints will help to ensure proper bonding as the adhesive sets up.

- Roll the glued areas right away to within 6" of the seam on either side with a 3 section 100 lb. roller. Roll the seam area with a hand-seam roller to bring the seam edges to equal heights. Re-roll the entire glued floor area with the 100 lb. roller within the working time of the adhesive. Continue to roll the floor throughout the working day to ensure a great bond.

- Heat weld seams the following day. See heat weld instructions.

- Contact Shaw product support for assistance if not familiar with scribing techniques or heat welding.

HEAT WELDING:

- Professionally heat welded seams provide a strong, watertight, hygienic, monolithic surface.

- The welding rod (4 mm) is designed to melt at the same temperature as the sheet flooring, thermally fusing the two together.

- Heat welding should be done 24 hours after installation using 2200,4200 or 4151.

- Seam edges should be slightly gapped and vertical. Wide gapped or undercut seams will prevent quality welds.

- The depth of the groove should be 1/2 to 2/3 the thickness of the material using a 3.5 mm grooving tool. Be careful not to go too deep. The groove must also be centered along the two edges.

This is very important to ensure proper strength and bonding of the welding rod.

- Clean grooves thoroughly of all foreign contamination, including dust.

- DO NOT groove into the “Closed Cell Foam Backing".

- Use only professional quality welding equipment that will maintain sufficient temperatures. A narrow preheat 4mm tip is required.

- Preheat welding gun prior to welding. Temperature should be set approximately 750°F.

- Practice on a scrap piece to fine tune temperature and pace. Long extension cords may affect welding temperature settings.

- Determine the correct welding speed by ensuring that the welding rod actually fuses into the groove. On the scrap practice piece try to pull the weld out of the groove. If the rod pulls out of the groove adjust temperature until it will no longer pull out of the groove.

- Tip must remain parallel to the finished floor. A small ridge must form on either side of the welding rod, at the urethane surface. If no ridge forms, you have not heat welded the seam correctly.

- While the welding rod is still warm, trim off 1/2 the excess rod with a spatula knife or Mozart skiver and trim plate in one continuous movement.

- After the rod has cooled to room temperature, make the final trim pass using a razor sharp spatula knife or Mozart skiver in one continuous movement.