Drop And Lock Installation Instructions

I. Pre Installation Guidelines

These installation instructions apply to the COREtec® Drop and Lock product. All instructions and recommendations should be followed for a successful installation. Flooring material should be inspected prior to installation for color, finish and quality. If flooring is not acceptable, contact your supplier immediately and arrange for replacement.

Required tools: Tape Measure, Pencil, Chalk Line, Circular saw, 3M Scotch-Blue™ 2080 Tape, Rubber Mallet, and 1/4” Spacers.

- Frequently moved furniture should be equipped with felt pads to avoid scratching the floor. Heavy furniture and appliances should be equipped with non-staining large surface floor protectors. Furniture with castors or wheels must be easy swiveling, large surface nonstaining and suitable for resilient floors. Do NOT use ball type castors as they can damage the floor.

- This product can be installed on, above, or below grade.

- COREtec® floor covering is an interior product and must be stored/installed in a temperature-controlled interior environment, maintained between 55 and 85 degrees F or 13°-29°C.

- Excessive moisture in the subfloor could promote mold, mildew, and other moisture related issues that will contribute to an unhealthy indoor environment. COREtec® is not responsible for damages related to these moisture issues. COREtec® recommends a 6 mil polyfilm when installing over concrete subfloors.

- Avoid prolonged exposure to direct sunlight as this will result in discoloration and expansion. The use of drapes, blind systems or protective window film is required.

- Flooring should be installed after all other trades have completed work that could damage the flooring.

- All subfloor patching must be completed with a Portland based compound and fully dried/cured prior to installation.

- Flooring material should be inspected prior to installation for color, finish and quality. If flooring is not acceptable, contact your supplier immediately and arrange for replacement.

- Crumb rubber underlayments are not an acceptable option for use with resilient floor coverings due to performance issues resulting from chemical incompatibilities.

II. Subfloor Preparation

All subfloors must be clean, flat, dry and structurally sound. Proper subfloor preparation is a major part of a successful installation. Subfloor must be flat – 3/16” in 10’ or 1/8” in 6’.

A. Over Existing Floors

- Installation is NOT allowed over any type of carpet.

- COREtec® flooring can be installed over most existing hardsurface floor coverings, provided that the existing floor surface is clean, flat, dry and structurally sound.

- If the adhesive residue is asphalt‐based (cut‐back), or any other type of adhesive is present, it must be removed by industry accepted methods such as mechanical removal or wet scraping.

- If a chemical abatement has been performed, use Shaw Surface Prep EXT to remove any residual chemicals present. Once Shaw Surface Prep EXT has been properly cleaned and removed, apply one coat of Shaw MRP for additional protection.

- Adhesive removal through the use of solvents or citrus adhesive removers is not recommended. Solvent residue left in or on the subfloor may affect the new adhesive and floor covering.

WARNING! DO NOT SAND, DRY SWEEP, DRY SCRAPE, DRILL, SAW, BEAD BLAST ORMECHANICALLY CHIP OR PULVERISE EXISTING RESILIENT FLOORING, BACKING, LINING FELT , ASPHALTIC “ CUT BACK” ADHESIVES OR OTHER ADHESIVES.

These products may contain either asbestos fibers and/or crystalline silica. Avoid creating dust. Inhalation of such dust is a cancer and respiratory tract hazard. Smoking by individuals exposed to asbestos fibers greatly increases the risk of serious bodily harm. Unless positively certain that the product is a non‐asbestos‐containing material, you must presume it contains asbestos. Regulations may require that the material be tested to determine asbestos content and may govern the removal and disposal of material. See current edition of the Resilient Floor Covering Institute (RFCI) publication Recommended Work Practices for Removal of Resilient Floor Coverings for detailed information and instructions on removing all resilient covering structures. For current information go to www.rfci.com.

DO NOT install over sleeper construction subfloors or wood subfloors applied directly over concrete.

- Existing sheet vinyl floors should not be heavily cushioned. Soft underlayment and soft substrates will diminish the products inherent strength.

Radiant Heating: Radiant-heated subfloor systems can be concrete, wood or a combination of both.

The heating systems components must have a minimum of 1/2" separation from the flooring product. The system must be on and operational for at least 2 weeks prior to installation to reduce residual moisture. Three days prior to installation lower the temperature to 65 degrees, after installation gradually increase the temperature in increments of 5° F to avoid overheating. Maximum operating temperature should never exceed 85°F. Use of an in-floor temperature sensor is recommended to avoid overheating. Contact the manufacturer of your radiant heating system for further recommendations.

-

Electric Radiant Floors: consist of electric cables (or) mats of electrically conductive materials mounted on the subfloor below the floor covering. Mesh systems are typically embedded in thin-set. When embedding the system components, use cementitious patching and leveling compounds that meet or exceed Shaw’s maximum moisture level and pH requirements. Use of gypsum-based patching and/or leveling compounds which contain Portland or high alumina cement and meet or exceed the compressive strength of 3,000 psi are acceptable.

-

Hydronic Radiant Floors: pump heated water from a boiler through tubing laid in a pattern under the flooring. Typically installed in channels under a wooden subfloor (or) imbedded in concrete slabs.

III. Installation

COREtec® is engineered to be installed utilizing the Drop and Lock Method.

A. Installing the first row

- Starting from the left with the tongue facing the wall, carefully place the first plank in place using spacers to leave 1/4” gap between wall and edges of the plank. (Figure 1)

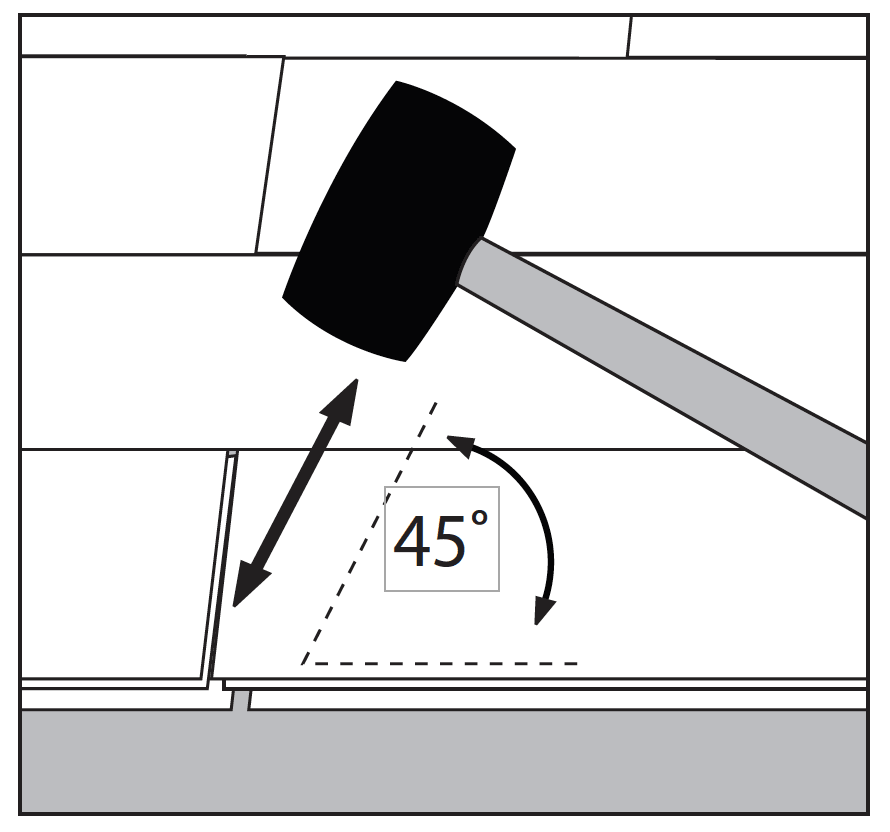

- Align the next piece by overlapping the end of the first board. Tap the joint with the rubber mallet using a downward angle striking motion towards the adjoining tile (Figure 5) until the tongue and groove lock together to secure the joint on the ends. Continue in this manner until reaching the final plank in the first row.

- Cut the final plank piece to length.

B. Continuing the installation

- Begin the second row with the cut piece left over from the first row if it is at least 8” in length. If the cut plank is shorter than 8” do not use it. Instead, begin with a new board that is at least 8” in length and allow 8” between the end joints on the adjacent planks.

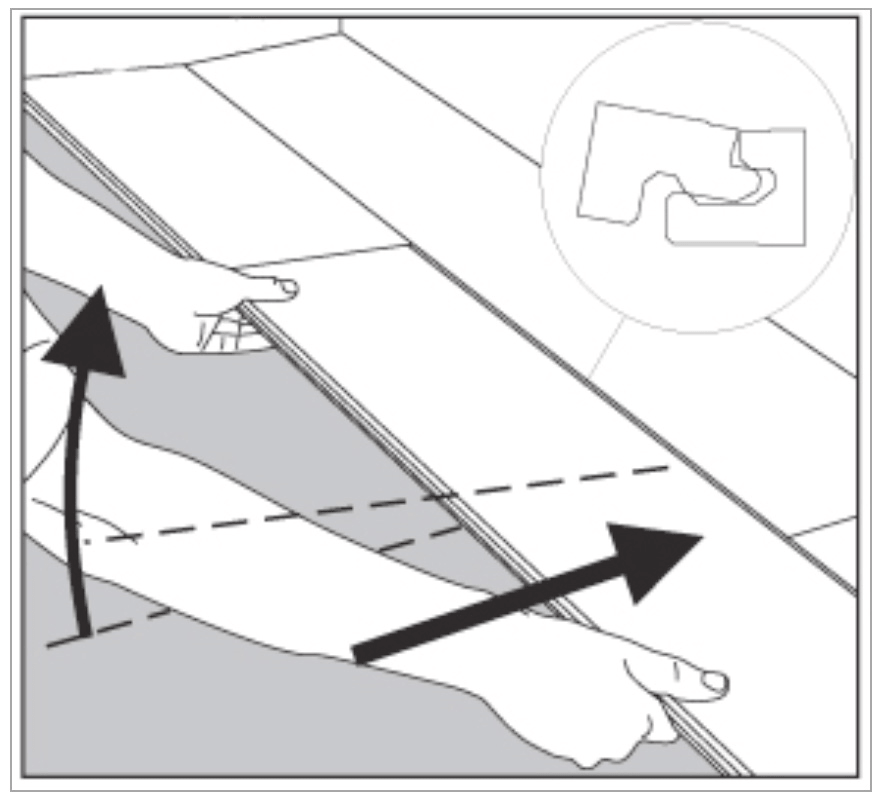

- Position the first board in place by angling it up slightly, pushing forward and interlocking the side tongue (Figure 2). The long side of the plank MUST BE SNUG against the adjoining plank with NO GAPPING. There will be a slight click when the long side is fully engaged and lowered into place.

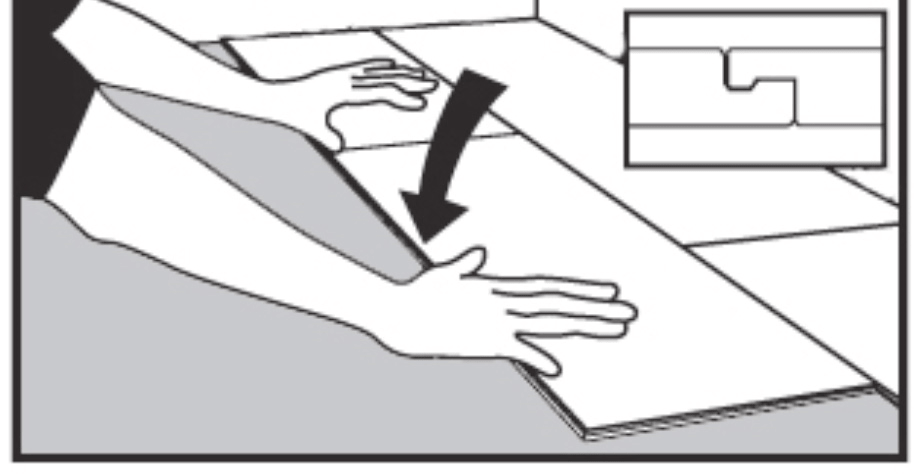

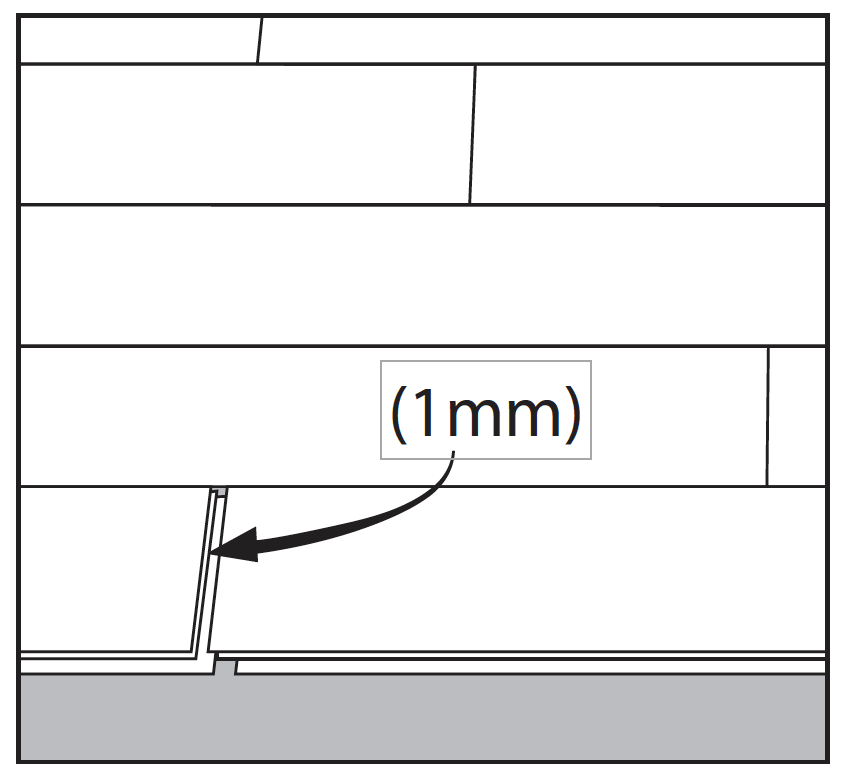

- Lower the plank (Figure 3) and slide the plank to the left to within approximately 1 mm of the end joint of the adjoining plank. (Figure 4)

- Tap the joint with the rubber mallet using a downward angle striking motion towards the adjoining end joint (Figure 5) until the tongue and groove lock together on the side and ends.

- Carefully inspect the long edge and short ends of the plank for any gapping before moving on to the next plank. If you notice a gap, STOP, and reinstall the plank to ensure a snug fit.

- Install the remaining planks and rows in the same manner. (Figures 2-5)

- Cut the last plank to size.

- Whenever practical, use cut pieces from previous rows as the starter board to reduce waste.

- Maintain proper spacing of at least 8” between end joints for best appearance.

C. Installing the final row

- The last row may need to be cut lengthwise (ripped).

- Place the last row of planks to be fit on top of the last row of installed planks. Use a piece of plank as a scribe to trace the contour of the wall.

- Mark where the plank will be cut. If the fit of the wall is simple and straight, simply measure for the correct fit and cut.

- After planks are cut, position planks and tap all joints (long and short ends) with the rubber mallet.

Installing under a door jamb

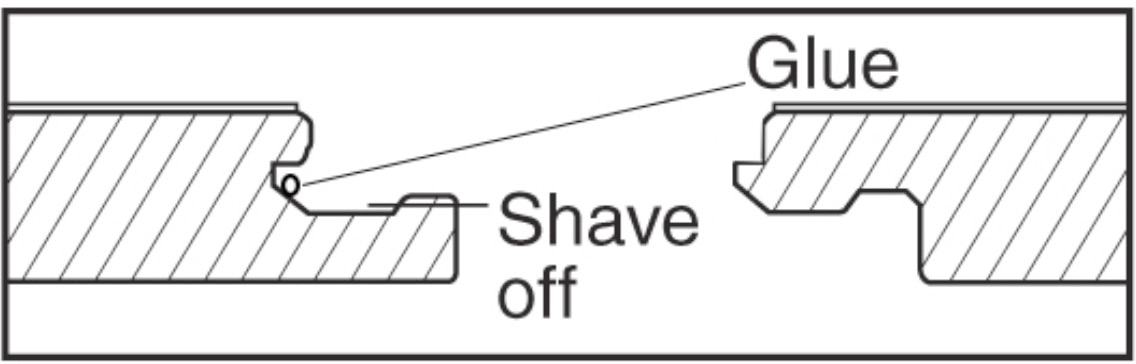

- Installation under moldings (such as door jambs) may require that the top lip of the groove on the end be reduced in size.

- Using a small plane or knife plane, carefully shave off the ledge of the groove. (Figure 6)

- After the groove ledge has been trimmed, place the plank in place and tighten with a pull bar. The installer must be sure that the required expansion gap has been maintained and the flooring is not pinched.

- If fit is not correct, re-trim as necessary.

- Place a bead of glue made for non-porous surfaces (i.e. GORILLA Super Glue Adhesive) as shown in Figure 6.

- Insert the tongue into the groove and engage with a pull bar. Hold the plank in place with painter’s tape (3M Scotch-Blue™ 2080 Tape) until the glue is dry. Do not use masking tape or duct tape as they may damage the floor’s finish.

Figure 1

Figure 1

|

Figure 2

Figure 2

|

Figure 3

Figure 3

|

Figure 4

Figure 4

|

Figure 5

Figure 5

|

Figure 6

Figure 6

|

NOTE:Adhering tape to the surface of your resilient flooring could damage the surface.

Do not use tape to secure floor protection directly to the floor during construction or renovation. Instead, adhere tape to the material used to protect the floor and secure it to the base molding along the wall. A material such as ram board can also be used to protect your flooring.